Our Mining & Electrical Projects

MAJOR ELECTRICAL IS PROUD TO WORK IN CONJUNCTION WITH VARIOUS PUMPING & WATER TREATMENT COMPANIES IN MACKAY AND SURROUNDING AREAS TO OFFER A COMPREHENSIVE SERVICE.

Our dedication to safety and high-quality work extends to our partners through our compliance with ISO9001 as well as the WHS Regulation and Act.

MAINS DE-WATERING PUMP STATION

A Dual 200kW DOL De-watering Station with two spare 30kW cubicles. It was

manufactured and supplied for Pit Bottom De-watering. The Pumping System was designed to Pump water that is created through the mining process or seeps into the mine. Collected at smaller remote pumping stations and lift this waste water up to 300m vertically out of the mine to surface waste water holding dams.

FLP PUMP PODS

This project that was requested in March 2016 for the supply and manufacture of an Ex ‘d’ (Flameproof) Pump Pod. This was a combined project with Dowdens Pumping.

Dowdens were responsible for the mechanical aspects of the project, while Major Electrical designed and supplied the electrics. This project was completed and delivered in April 2016.

DUAL 45KW VSD STARTER

This Dual 45kW VSD Longwall Booster project was requested to address Longwall water pressure supply issues. The pump was to be installed along the main gate roadway within 4km of the working face for optimum effectiveness. This setup is powered through a 1000V 425A receptacle and feeds two 45kW VSDs/ motors and associated control circuits. Each drive can be isolated locally at the starter panel or the entire system can be isolated at the substation outlet from which the installation is fed.

IP PUMP STARTERS

This project was successfully tendered in March 2016 for the supply and manufacture of an IP55 Pump Pod for the purpose of underground De-watering. This project was completed in conjunction with Dowdens Pumping, who were responsible for the mechanical aspects of the project, while Major Electrical designed and supplied the electrics.

FLP PUMP POD

This Project was the introduction of our MJE 100 Series Flameproof Enclosure to the industry. A new enclosure design was required to allow enough room to house all critical electrical components while also enabling access for maintenance. The order was raised in December 2016

and final commissioning and delivery was in February 2017. The scope also included a full mechanical overhaul which was completed in our Paget facility. This was the first of five enclosures successfully tendered for this project.

AS3800 PUMP POD OVERHAUL

This project was an overhaul requested for a streamlined flameproof pump station with 6 cubic meters of storage and an 110KW motor. It was requested for use in the development section of the mine and pumped waste water out to the pit bottom De-watering station. From here it was ready for pumping water out of the mine. It was quoted in October 2016 and was manufactured in conjunction with Dowden’s Pumping, who were responsible for the mechanical aspects of the project, while Major Electrical designed and supplied the electrics. This project was successfully completed in June 2017.

ATF800 PUMP POD OVERHAUL

Major Electrical was engaged by Dowdens Pumping and Water Treatment to complete a full AS/NZS 3800 overhaul on an ATF 800 Series Pump Starter. As part of the overhaul it was stripped, measured and inspected. All components, cabling and new accessories were tested for re-use or replaced with new components.

IP BUILDS

OVER THE YEARS WE HAVE WORKED ON VARIOUS PROJECTS FOR THE MINING INDUSTRY THAT NEEDS INGRESS PROTECTION AGAINST DUST AND WATER IN AND OUT OF EXPLOSIVE RISK ZONES.

We pride ourselves on our manufactured IP Builds that are fabricated to your specifications for your next project.

IP PUMP STARTER

Major Electrical was engaged to design, manufacture and supply two IP55 1000V 18.5kW Pumpstarters with external LED Lighting.

These Pump Starters were supplied on transport skids which were to be positioned near the separate tank and motor skids. 17m

Weiland plugs were used for the connection of all monitoring devices to allow a plug and play type system.

It was provided with a 20m string of STRIP-R lighting to be fitted in the cut-through on site to illuminate the full installation.

MAINS DE-WATERING PUMP STATION

A 200kW DOL dual motor starter with onboard PLC, a SCADA system with a CISCO switch and fiber card. This allowed data from the pumping installation to be sent to the surface of the mine and monitored on a CITEC display. This then allows access to a display that shows the condition and operation of the system.

This project was commissioned in Feb 2015 and was completed in June 2015.

REMOTE ISOLATION ENCLOSURES

For this project, Major Electrical was engaged, to design and manufacture two Remote Isolation Enclosures. These were to be utilised for a Tunnel Boring Machine.

The first unit was to enable the remote isolation of the 415V feeder to the TBM. This was attained via the use of three 3200A motorised ABB Emax 4.2 Circuit Breakers to achieve an effective remote isolation capability.

LED STRIP LIGHTING

LED STRIP LIGHTING STRIP-R LIGHTING IN NON-EXPLOSIVE RISK ZONES HAS SPECIAL INSTALLATION REQUIREMENTS DUE TO THE LENGTH OF STRIP REQUIRED TO ILLUMINATE THE VAST DISTANCES.

Major Electrical has extensive experience in installing and managing LED Lighting in the mining industry.

STRIP-R LIGHTING

Major Electrical was engaged to provide a design and the supply of roadway lighting for the Transport Drift, Conveyor Drift and Travel Road Lighting of an underground colliery.

Major Electrical manufactured 50 lighting enclosures and supplied 4kms of STRIP-R Lighting, using STRIP-R (36V 60LEDs/M) Lighting Strings. This gave an approximate LUX level of 38 LUX per meter underground. STRIP-R Lighting, is an LED strip lighting for non-explosive risk zones. The best lighting available in the STRIP-R range is 60 LEDS per meter. This was used in this project to achieve optimum lighting for the area.

VENTILATION AND FANS

New Paragraph

MAJOR ELECTRICAL IS ONE OF THE LEADING PROVIDERS OF MINING AND COMMERCIAL FAN AND VENTILATION OVERHAULS.

Combining years of experience, design and customer service with welltrained employees and safety protocols. Major Electrical can take on any project and deliver innovative and cost effective solutions.

TRACK AUX FAN UPGRADE

Major Electrical was engaged to scope and overhaul a 22m/3 Aux Fan. This lead to the opportunity to assist their site process in panel advancement. The site wanted to move to a system of a self-propelled track unit. We came up with a design and layout of components to ensure a successful outcome. This was achieved by the acquisition of a track base and hydraulic system. The Fan was designed with dual run

modes, tramming and fan mode. Electrical interlocking was used to protect each mode. The system comprises of Headlights, Area Lights, Strobes and Sounder, Methane Monitoring and a hydraulic protection system incorporating level, temperature and pressure monitoring. The fan project was a great success and lead to the conversion of another four units onsite.

VSD BOOSTER FAN MOVE

Major Electrical was requested to electrically dismantle VSD Booster Fans #1 and #2 in preparation for moving the infrastructure to a new position on the Highwall. The task involved disconnection from the Mine’s High Voltage Distribution System. Once the VSDs and Fans had been

re-installed the Control and Gas Monitoring Systems were reconnected. Major Electrical performed beyond expectations against severe time constraints.

SWITCH ROOMS

MAJOR ELECTRICAL UNDERSTANDS THAT A SWITCH ROOM IS THE ELECTRICAL NERVE CENTRE OF A WORKSITE. THE TECHNOLOGY IT HOUSES IS OF CRITICAL IMPORTANCE.

That’s why we make sure that all of the switch rooms we design and manufacture are of the utmost quality. You can be sure that your critical services are safe.

At various predetermined intervals Inspection Audits were conducted to ensure compliance with ISO9001 Quality Management System and Industry Standards. Major Electrical also conducted various inspections throughout the build as per our ITP (Inspection Test Plan). The

complete manufacturing timeframe for the mounting platform and skid base, including galvanising, was 6 weeks. The Mine Goaf Dewatering Project was a design and construction project, which comprised many complex segments including Mechanical, Pumping, Civil, Structural, Fabrication, Design, Electrical, Communications, Manufacture and Installation.

Phase one of the installation of this project is scheduled for completion in July 2017. The final phase of this project is due for completion in 2018 to align with the Mines’ Longwall Activity. To date, the project has exceeded site expectations.

ONSITE WORKS

WHEN IT COMES TO ONSITE MAINTENANCE, REPAIRS, AND INSTALLATIONS, MAJOR ELECTRICAL CAN HELP.

Our team of diverse disciplines and skills enables Major Electrical to deal with onsite projects pertaining to a wide range of environments, from commercial to heavy industrial.

SURFACE EXTRACTION FANS UPGRADE & OVERHAUL

Major Electrical conducted a system upgrade to an 11kV to 433v main vent fan system. The purpose of this upgrade was to bring the system to the latest requirements and upgrade to the Siemens drive package.

Works included:

• Upgrade LV Drives

• Overhaul HT & TX End

• Upgrade HT End

• Upgrade Aircon System

• Overhaul & Upgrade Fan Works

• Site layout including Trenching, Earth Grids, Conduits & Lighting Protection System

• Modification & Overhaul of Fan Structures

MINE SITE BACKUP CONTROL ROOM

Major Electrical was employed to covert an existing site container into a backup control room.

Works included:

• Fabrication

• Cabinetry Works

• Design & Install Communications System

• Backup UPS System

• Site Installation & Integration

BULK AIR COOLERS

Major Electrical was engaged to construct an electrical for site bulk air coolers system.

Works included:

• 11kV Supply Feed

• Earth Grid & Lightening Protection System

• Upgrade & Install Kiosk Substation

• Install BAC to Shaft

• Knife Gate Design & Install

• Site Installation & Segregation

COAL POWER STATION HAZARDOUS AREA TRIPPER UPGRADE INCLUDING SLOT BUNKER LIGHTING

Major Electrical was contracted to design and construct a hazardous area system upgrade for a coal fired power station. The bunker and lighting system that was originally installed was a non-hazardous area system. Major Electrical designed and converted the electrical system to become compliant to the current hazardous area zoning standards. This installation was completed in the plants scheduled maintenance shutdown including rotating 12 hour shifts between two crews without any safety incidents. The completion of the job was done to the highest level of workmanship and came in on time and on budget.

Works included:

• Upgrade lighting system to be HA LED

• Supply new ex rated components boards

• Installation of system

• HA documentation

• New cable festoon system 200M

FLAMEPROOF BOXES

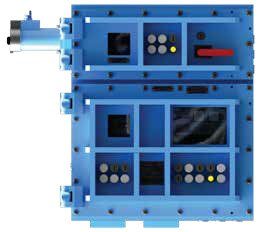

ENCLOSURE A

Enclosure A has approximate dimensions of 850 mm wide x 660 mm high x 400 mm deep and contains electrical equipment such as a circuit breaker, PLCs, control relays, a transformer, control components, displays, switches, terminal strips etc. The enclosure has a hinged and bolted door fastened to the front of the enclosure via eighteen M16 socket head cap screws. The door is reinforced with external braces welded to the door and may incorporate up to one large and one small polycarbonate viewing windows. Metric threaded entries are provided in the door for the fitting of separately certified devices. Metric threaded entries may be provided in the enclosure side walls and top, bottom and back plates for the fitting of separately certified devices. Mounting pads consisting of plates welded to the enclosure may be provided on

the enclosure side walls and top and bottom plates for the fitting of separately certified receptacles and cable coupling devices. A main circuit breaker operator may be provided in the sidewall.

ENCLOSURE B

Enclosure B has approximate dimensions of 850 mm wide x 370 mm high x 400 mm deep and contains electrical equipment such as a circuit breaker, PLC, Ethernet switch, control relays, a transformer, a display, control components, switches, terminal strips etc. The enclosure

has a hinged and bolted door fastened to the front of the enclosure via fourteen M16 socket head cap screws. Metric threaded entries are provided in the door for the fitting of separately certified devices. A main circuit breaker operator may also be provided in the enclosure

door. Metric threaded entries may be provided in the enclosure side walls and bottom plate for the fitting of separately certified devices. Mounting pads consisting of plates welded to the enclosure may be provided on the enclosure side walls, top and bottom plates for the fitting

of separately certified receptacles and cable coupling devices.

ENCLOSURE C

Enclosure C has approximate dimensions of 850 mm wide x 250mm high x 400 mm deep and contains electrical equipment such as a circuit breaker, a transformer and switches. The enclosure has a hinged and bolted cover fastened to the top of the enclosure via sixteen M10 socket head cap screws. Metric threaded entries may be provided in the enclosure top, bottom, front and back plates for the fitting of separately certified devices. Mounting pads consisting of plates welded to the enclosure may be provided on the enclosure side walls and top plate for the fitting of separately certified receptacles and cable coupling devices. A main circuit breaker operator and pushbutton and switch operators

may be provided in the front plate of the enclosure.